Various Types of EPOXY FLOORING

When it comes to selecting new flooring for use in industrial areas or garage floor coating or any other outdoor surface Epoxy resin flooring sets itself apart in comparison to other floor options due to several reasons. Epoxy flooring, also known as resinous flooring, is durable, adaptable, and attractive to any kind of floor. The thing that draws people to epoxy flooring is its resistance to extreme degrees of wear, which makes it the longest-lasting flooring choice. If you’re thinking about epoxy flooring, here’s an explanation of the components that epoxy flooring is composed of, as well as the different kinds of epoxy resins, and which areas to utilize specific kinds of flooring made from epoxy. Learn more at Local Epoxy Pros

“What is Epoxy?”

One of the most significant aspects of an epoxy coat is the fact that it’s chemically different from standard floor paints. Resinous flooring comprises two components of the epoxy system: composed of hardeners and polymer resins similar to epoxy glue. When properly mixed, hardener and epoxy resin react with one another and form the formation of a chemical bond between each compound as well as the floor. The chemical bond forms a rigid plastic that is strong, durable, and resistant to degrading, and bonds extremely well to the substrate.

“What is Epoxy Flooring?”

The simplest term for epoxy flooring is the flooring surface is comprised of many layers of epoxy which is sprayed on a floor that is two millimeters or more. There is often confusion when the two are compared: an epoxy floor and an epoxy floor coating. The difference is the thickness of the epoxy. As said epoxy floors are defined as an epoxy coating minimum of two millimeters in thickness. Any floor made of epoxy that is less than 2 millimeters is often called an epoxy flooring coating.

Types of Epoxy Flooring & Where to Apply Them:

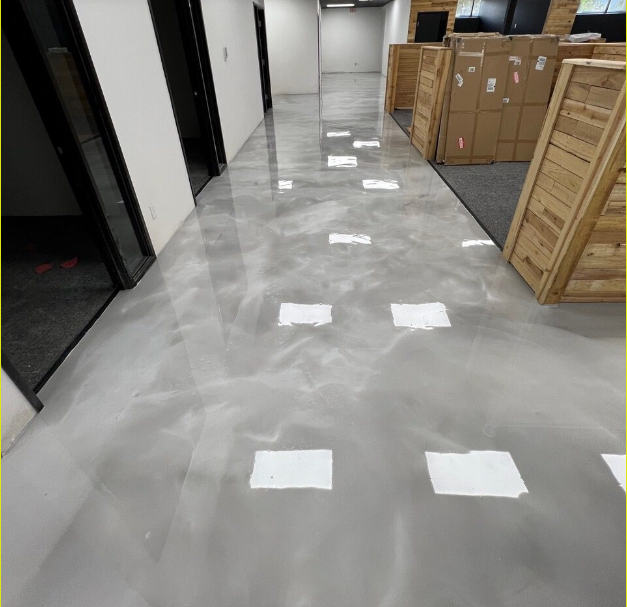

Self-Leveling Epoxy Floors: self-leveling is used to cover old, new, cracked, or damaged concrete floors to provide a smooth, sturdy, and level look on the floor’s surface. Self-leveling floors not only offer a smooth, shiny appearance but also come in a variety of shades that are appealing to industrial, commercial, and residential areas.

Where To Use Self-Leveling Epoxy Floors: Manufacturing facilities warehouses, showrooms, warehouses restaurants, commercial garages, athletic facilities, and many more.

Epoxy Mortar Floors: This flooring type is classified as the strongest epoxy floor option that is available. This floor is made from all-solid epoxies and quartz sand that has been graded or graded. Mortar flooring is ideal for areas that require flooring which is resistant to chemicals and can withstand a significant amount of pressure. This floor is used to repair cracks prior to applying a different kind of flooring made of epoxy.

Where To Use Epoxy Mortar Floors: mechanical spaces, commercial kitchens, warehouses, garages, restaurants, and manufacturing facilities.

Quartz-Filled Epoxy Floors: Flooring made from quartz epoxy is made up of high-performance epoxy resin as well as the stained grains of quartz. This type of epoxy should be used for areas with a decorative appeal that require slip-proof and sanitary characteristics.

Where to Use Quartz-Filled Epoxy Floors: restrooms, locker rooms, cafeterias, schools, showrooms, offices and lobbies, and much more.

Anti-Static Epoxy Floors (Electro-static charge (ESD) Resistant Floors): ESD can be dangerous to many working environments. To minimize the risk of static within your workplace Anti-static epoxy floors may be installed. This floor is typically the conductive substance that creates static electricity and disperses any discharge that could occur. Anti-static flooring is an extremely suggested epoxy floor for areas where there are flammable materials.

Where to Use Anti-Static Epoxy Floors: electronic, chemical manufacturing facilities, pharmaceuticals as well as healthcare facilities. Any other areas that contain gas or liquids that are flammable and can cause an accumulation of combustible dust.

Epoxy Flake Floors: It is a type of flooring that has colored flake material that is embedded in the epoxy to create a vivid multi-hued appearance. They not only provide a unidirectional look but also provide the floor with subtle grooves, which help to prevent any falls and slips. Epoxy flake flooring comes in a myriad of sizes, colors, designs, and textures that are customizable to fit any room.

Where To Use Epoxy Flake Floors: locker rooms, showrooms, sports arenas, commercial kitchens, clinics, and more.

Flooring made from epoxy can be a flexible chemical that is practical, durable, resilient to impact, and apprehensive for every space. If you want an elegant entrance to your restaurant or require durable flooring that can withstand the rigors of heavy industrial use, there’s an epoxy flooring solution that is suitable for the space you’re in.

FIVE KEY PARTS OF OUR SUPERIOR EPOXY KITS

We put lots of effort towards becoming one of the leading experts in flooring coatings made of epoxy.

We’ve also worked on making these products easy and appealing to our clients. Take a look at our customer reviews or explore other sections on our site to learn more about how we assist our clients when they require to reinvent their interior spaces by refinishing concrete floors using the latest epoxy flooring.

Here are a few things we’ve included with our kits for the epoxy to ensure you get the most out of the products you purchase.

QUALITY PAINT BRUSH AND ROLLER

In the case of the application of your work, it will benefit from the highest quality tools. We’ve included an adequate-sized and well-constructed paintbrush as well as an extra wide roller and an excellent frame. These tools will be worth it when you put them on your sleeves!

GLOVES

This kind of personal protection equipment is useful in the event of an outbreak, but it’s beneficial for handling floors coated with epoxy. We supply gloves for security, as well as to prevent things from getting messy when you’re working on the floor coating plan. Cleaning up the mess is also a way of speeding up the process in general and therefore, these gloves are great to keep in your kit.

METAL POWER MIXER

Two-part epoxies require an exclusive mixing procedure, mixing quality is vital also, which is why we have this compact but powerful mixing tool that can help our customers make these projects efficiently and with less trouble. Have you ever attempted mixing epoxy using an old cardboard piece? If so, you’ll know the reason this tool is so beneficial in this type of work.

SPIKED SHOES

While you move around your area the spiked shoes we offer as part of our epoxy kits can help you keep your equilibrium. These are mentioned on the internet. as a crucial component of the floor, coatings made with epoxy. Our spiked shoes offer top-quality support to our project managers, whether at home or wherever else they are.

ACID ETCH SOLUTION

To eliminate the need for the initial coating, an acid formulation is an integral part of the epoxy set. It is a service we provide to make sure that our customers have the right support when implementing their chosen coatings. Contact us with any questions you may have, and then use our up-to-date, reliable online portal to access everything you require in one step.